The structure of the model setup and the various interfaces - namely Laminar Flow, Phase Field, and Moving Mesh - is shown in the screenshot below: An Outlet boundary condition is used for the boundary corresponding to the top of the beaker. The Wetted Wall boundary condition of the Phase Field interface lets us specify the contact angle between the water surface and the solid walls, while the Wall Movement setting in the Wall boundary condition of the Laminar Flow interface lets us specify the velocity of the moving solid walls. The Laminar Two-Phase Flow, Phase Field interface enables us to model the boundaries of the sphere as moving wetted walls.

#Laminar flow module comsol 5.3 how to

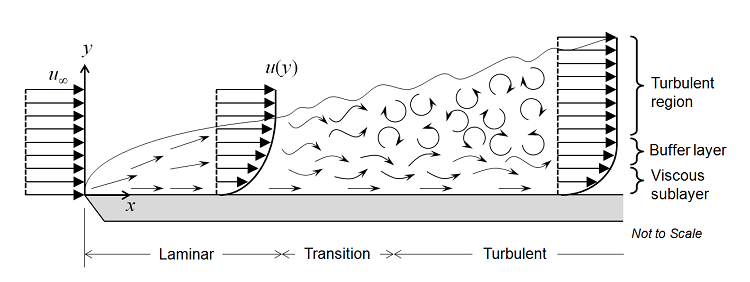

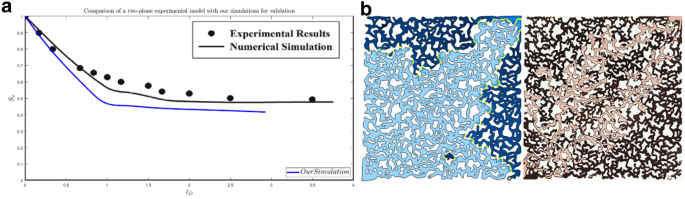

(Read this blog post on how to choose a multiphase flow interface for more information.) This multiphysics interface automatically defines a coupling between the laminar flow and phase field method, which is used to track the detailed shape of the water surface. The fluid flow in this case is laminar, in both the air and water phases, so we can use the Laminar Two-Phase Flow, Phase Field interface. The sphere is represented as a boundary in the model domain because we are modeling it as a rigid object using ODEs. Geometry of the 2D axisymmetric model showing the initial position of the water surface represented by the horizontal line. To model this problem, we couple a Two-Phase Flow interface with a Moving Mesh interface and Global Equations by defining the coupling expressions illustrated in Eqs. We can set up the above problem as a 2D axisymmetric analysis. The force F z can be calculated by integrating the z-component of \mathbf = \left(0,v_s\right) Setting Up the Model in COMSOL Multiphysics® Where m denotes the mass, v s the velocity in the z direction, and u s the displacement in the z direction of the sphere. The total fluid stress exerted by the fluids on solid boundaries is given by If we consider the sphere to be rigid, we can compute the motion of it by solving the ordinary differential equations (ODEs) of motion that account for the force experienced by the sphere falling through the air, hitting the water surface, and finally interacting with both air and water. To model the motion of the sphere through the water surface, we need to model the fluid flow in both the air and water phases. A larger system can be modeled in exactly the same way, but would require more computational resources. The size of the system is small enough to assume laminar flow and also allows for a faster solution process on a regular PC. The cylindrical beaker has a radius of 0.65 cm, a height of 1.7 cm, and is partially filled with water. The sphere, with a radius of 0.15 cm and density of 800 kg/m 3, is initially suspended in air. Let’s consider a buoyant sphere that is dropped into a water-filled beaker. Oscillating Motion of a Buoyant Sphere: A CFD Problem Although we are considering the case of a small sphere, the technique discussed here can be applied to other larger shapes as well. How do you model the resulting shape of the water surface and the motion of the sphere as it floats on the surface? In this blog post, we demonstrate how to model this system in the COMSOL Multiphysics® software. A report can be generated that includes the app setup and results through the click of a button.A sphere slightly lighter than water is dropped into a small liquid-filled beaker.

After computing the results, you can visualize Whirl and Campbell plots and review a table of critical speeds that are dependent on the input parameters. The application uses the Beam Rotor interface.

The app automatically creates the geometry and sets up the physics based on the information provided in the inputs. This can be done through manually specifying the data or uploading it from a file. You can input the geometrical dimensions and stiffness of the rotor, position and inertial properties of the bearings and disks, and other material properties by choosing a predefined material from a drop-down menu. An eigenfrequency analysis of the system is performed by the app at different angular speeds to find the critical speed of the rotor. It is useful for the preliminary design stage of rotating systems to ensure that the system's critical speed is not in the region of its operating speed.

#Laminar flow module comsol 5.3 simulator

The Rotor Bearing System Simulator is an example of an app that can be used to design and analyze rotor systems consisting of a rotor and different disks and bearings.

View screenshot New App: Rotor Bearing System Simulator

0 kommentar(er)

0 kommentar(er)